Boots that fly. Shoes. Professional anti-slip shoes

Shoes are an element of clothing. Fits on feet. It is used primarily for thermal and mechanical protection of the legs. But if someone doesn’t have enough of these features of shoes, he can come up with others: lighting, sound, special shape, jet engines, and even built-in massagers with Bluetooth transmitters. Scientific and technological progress leaves its mark on all types of human activity, and shoes are no exception.

It seems that we are already accustomed to charging smartphones, tablets, scales and even toothbrushes - this is a fee for the presence of "smart" functions in a particular device. But what if you have to monitor the charging of your sneakers as well? One such model - Adapt BB, was shown by Nike. not only can they tie their shoelaces themselves, but they are also “friendly” with the smartphone application.

Nike has announced that it is about to begin selling a new self-lacing shoe that was inspired by the pair worn by Michael J. Fox in Back to the Future II. Nike's Heidi Bergett tweeted that the HyperAdapt 1.0 will be available for purchase starting November 28, but only at select retailers in Nike. The sneaker's price hasn't been revealed yet, but according to the sneaker's creation article, it's safe to expect a "high price tag."

Dirty shoes are bad news, well-cleaned shoes are good news.

Imagine that you are washing your shoes and polishing them with shoe polish until they shine.

Buying shoes - to improve all things: wooden - to avoid danger in your personal life.

Buy over the knee boots - claims from the authorities, which put you in a difficult position, will turn out to be groundless; men - you will find a new job that will be the beginning of your career.

Buying a child - good news will lead to an increase in your well-being.

Trying on shoes - to increase salaries.

Visualize shoes purchased in a dream. Remember how comfortable you felt in them.

Putting on new shoes - for an early marriage: black - with the owner of a stubborn and quarrelsome character.

Wear white shoes - with the owner beautiful appearance; red - with the owner of a cheerful and cheerful disposition.

Wear boots from genuine leather- with the owner of numerous relatives; lacquer - with a person from another country.

New shoes are tight - the marriage will not last long.

Imagine how you carefully, lovingly put on your new shoes. Mentally rub them to a shine.

Loss of shoes - real losses await you in reality: new shoes - a profitable business will fail; old shoes - a break in relations with a close friend.

The loss of high boots or boots - arrived in a business that promised to be successful.

Loss of one shoe - part of the property; left barefoot, walking in the darkness of the night - the collapse of all plans and hopes.

A shoe that has flown off your foot - a neglect of others will lead to loss of health and disappointment.

Shoes require repair - intrigues are woven against you and clever traps are set on the way to your success in life.

Repair yourself - the problems that have piled on you will lead to a breakdown.

Give it for repair - there will be big chores that will lead to a quarrel with colleagues.

Mentally prolong the dream and imagine that you have been presented with new shoes (see Gift).

Walking in boots - tests await you that will be provoked by your indiscretion.

Being in other people's shoes is a quick trouble in matters of the heart; in old and dirty - your criticism will increase the ranks of your enemies.

To be in tight boots - you will become a universal laughing stock; in unlaced shoes - losses and a long illness await you; in worn shoes - quarrels with superiors.

Your shoes are wet - treason loved one; in shoes that you don’t like - a break in relations with a person who is very dear to you.

Being in old-fashioned shoes is the collapse of your old dream; in torn shoes - the consequences of an unsuccessful trip will not keep you waiting.

Imagine that you are walking in boots under an autumn downpour (see Autumn, Downpour).

Interpretation of dreams from the Dream Interpretation of Simeon ProzorovSubscribe to the channel Dream Interpretation!

Dream Interpretation - Boots

If you dreamed that you lost your shoe, then very soon you will be invited to romantic dinner. So that you don't have to wait long for an invitation, put some salt in your shoes and leave them on until the sun goes down.

If you dreamed that you were repairing a shoe, then a very difficult time awaits you. To make it a very short time, pour salt into your old shoe and burn it in the cemetery.

Interpretation of dreams from

1. Patterns of slippers

To build a pattern of slippers, you can use the above calculations, fitting them to your size.

Koshmina E.L., Ladanyuk A.A. Simple do-it-yourself shoes

If you have slippers of the style you need, and you would like to sew exactly the same ones with your own hands, then it is not necessary to build this pattern.

3. Threads and tools

How to sew pillow letters

DIY braided belt

DIY leather belt

How to sew curtains on grommets

How to make shoes non-slip?

When choosing shoes, we first of all pay attention to them. appearance, price and convenience. And only when we are in a new thing on the street, especially in ice, we begin to think about such important quality shoes, like non-slip soles. But slippery shoes threatens not only discomfort, but also the risk of injury when walking on the streets, especially for the elderly.

So how do you choose shoes that are sure to be non-slip at all times?

Winter non-slip shoes are characterized by a rather embossed sole with considerable flexibility, which provides good grip on any road and prevents slipping from bumps and bumps. If we talk about the material, then the polypropylene sole is considered less slippery than the rubber one. It is not advisable to give preference in winter high heels, because such shoes will not be stable enough and will begin to slip.

If you have already bought shoes and it turned out to be unstable - do not despair. There are several proven ways to make the soles of shoes non-slip. Conventionally, they can be divided into professional methods and folk advice.

- emboss flat sole you can do it yourself with a nail, grater or any sharp object. But do not overdo it, so as not to damage it too much, which may affect the moisture and heat resistance of the shoe.

- Use coarse sandpaper. It is useful not only for rubbing the sole and scratching it in this way, but also for sticking individual patches on the heel and toe, which will provide more comfortable movement in ice.

- Sticking materials such as fabric-based patches, felt, durable foam rubber or rubber to the sole will significantly reduce the sliding properties of the shoe.

- You can build improvised spikes on the sole. To do this, you need small screws and nails.

- The original method should be used if you have Moment glue. It consists in the fact that the specified glue is applied to a slippery sole over its entire surface with ornate patterns, and sprinkled with coarse sand or small pebbles on top. Leaving the shoes after that for a day to dry, you will get universal all-terrain vehicles.

- Surprisingly, rubbing the soles with raw potatoes also gives a good effect and helps to stay more stable on the ice.

As you can see, making winter shoes non-slip is not so difficult. For this, only desire and a few quite accessible materials are enough.

Professional anti-slip shoes

If you are not a fan of improvisations and are ready to fork out, then we hasten to please you: today, several varieties of special devices are on sale that will provide a non-slip sole for winter shoes. Among them are the following:

How to make slippers with your own hands

If you like to make original and unusual bags, covers, mittens and other products with your own hands, then making homemade slippers will not be difficult for you. Moreover, you can sew slippers, warm children's boots, ugg boots from any materials at hand, for example, from an old sheepskin coat or tops of women's leather boots.

Do not forget that old things, clothes, shoes are free material for sewing new clothes and needlework. See What can be sewn from the old.

This article provides two types of patterns for slippers, as well as the technology for their tailoring. Advice is given from what and how to make home slippers, warm children's boots with your own hands.

1. Patterns of slippers

To make a pattern of flip-flops with an open toe or a closed one, take a piece of paper and trace the outline of your foot. You can take old slippers (without a heel) of a suitable size, put them on paper and outline the sole.

If you draw your leg on paper, it is better if it is in a sock or stocking and it is advisable to sit on a chair to reduce the load on the foot. Then there will be no distortion in the size of future slippers on the pattern.

DIY shoes: How to make dream shoes at home

Outline the outline of the foot, and then check it. To do this, measure the distance from the edge of the thumb to the heel with a measuring tape or ruler. This value should correspond to the size of your shoes, for example, for size 43 shoes, this distance will be 28 cm with an error of half a centimeter.

To build a pattern of slippers, you can use the above calculations, fitting them to your size. If you have slippers of the style you need, and you would like to sew exactly the same ones with your own hands, then it is not necessary to build this pattern.

Wrap the top of the slippers tightly with paper or cloth, draw the outline of this part with a pencil or felt-tip pen and give allowances for the seams. After that, you can cut out this part, attach it again to the top of the slippers and check if it exactly follows its contour. Correct if necessary.

2. What can you make slippers from

For sewing home slippers you need to use various materials. The right and left parts of the bottom of the sole are cut from shoe leather, split leather, leatherette. Insoles (the upper part of the soles of slippers) are made of split leather, suede or cloth. There should be another padding between the insole and the sole. Usually it is cut out of cardboard and batting (a synthetic winterizer, thin foam rubber is also suitable).

The details of the top of the slippers are cut from leather and lining, they can also be duplicated with soft pads, then quilted.

If the top of the slippers consists of two halves, grind them off or connect them with a braid. They are glued with a gasket and lining, edging or braiding cuts (closed slippers have one cut, open slippers have two). Then a decorative finish is performed.

3. Threads and tools

In order to sew durable slippers, you need to use special extra strong threads. For sewing slippers, cotton threads in 6,9,12 additions No. 30, 40, 50 are suitable. Cotton-lavsan threads No. 44 LH-1, 65 LH-1 or lavsan threads No. 22 L, 33 L, 55 L, 90 L. For stitching parts the top of the slippers is best suited for nylon threads No. 65 K, 95 K. For stitching the soles, stronger nylon threads No. 470 K, 565 K are needed.

Top details, edging of cuts can be done on sewing machine, but you will have to manually stitch the top and piping to the sole. Therefore, purchase a special awl in the hardware store. With it, you can sew strong and durable slippers from any materials.

4. How to sew house slippers

After the pattern of the sole and top of the slippers is ready, you can start cutting out the details. When cutting the soles, give an allowance for processing the edge of 0.5 cm.

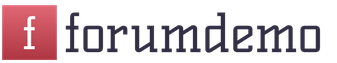

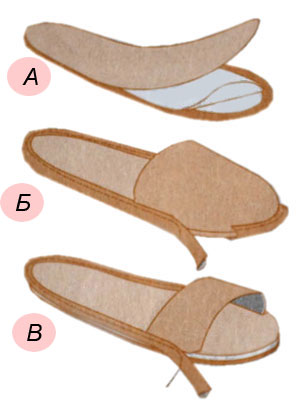

The gasket pattern is reduced by 0.7 cm along the entire contour so that the gaskets do not unnecessarily thicken the seam. Glue soles cut out of leather, cardboard, batting, split leather and trim the edges evenly (Fig. A).

Glue the sole along the edge with the top of the slippers with the seam outward (Fig. B), aligning the control marks. On a closed model, the excess length of the upper part is pre-fitted along the toe. If at closed top If you can allow some freedom for the leg, then in the model with an open toe, you need to adjust the length of the upper part so that it fits snugly around the leg.

The top is connected to the sole with an edge braid, piping, straight stitching. The welt can be made in the form of a piping or an overlay along the edge of the sole from a narrow leather strip (Fig. B). The seam can be closed with a decorative braid woven from thin leather straps, cords, ribbons, etc. To fix the finishing elements, you can use a glue gun for needlework.

As in any work with paired products, operations are performed simultaneously on one and the other slipper.

5. How to make a pattern of warm house boots

For those who prefer warmer indoor boots to slippers with an open back, the work is more difficult. You already know how to make a sole pattern, just outline the leg and add a seam allowance along the contour. But to make a pattern for the top of such slippers (such as uggs), complex calculations are needed. Therefore, we use better method"wraps".

For those who prefer warmer indoor boots to slippers with an open back, the work is more difficult. You already know how to make a sole pattern, just outline the leg and add a seam allowance along the contour. But to make a pattern for the top of such slippers (such as uggs), complex calculations are needed. Therefore, we use better method"wraps".

Since indoor shoes do not require snug fit to the leg, and even vice versa, then shoes or boots with flat soles may well serve as a template for removing the pattern of the upper part and further modeling.

First you need to wrinkle the paper so that it fits better on the convex surface of the shoe. Then wrap it around your chosen shoe or leg. Wrapping the leg is not very convenient, but the pattern is more accurate. If you are satisfied with loose and spacious boots, then use shoes for the template.

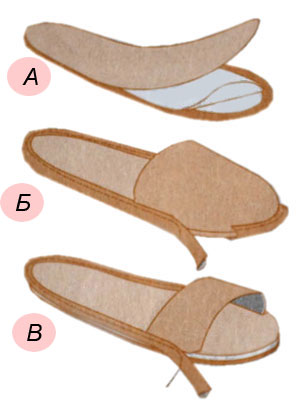

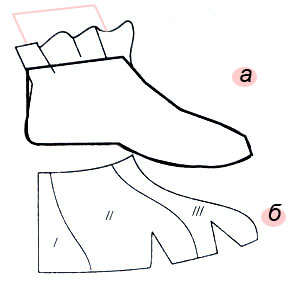

While wrapping the template, you can lay folds, fixing them with glue or paper tape, pins. Outline the connection line with the sole, the middle line along the front of the boot and along the heel, the contour of the upper edge of the boots (Fig. a).

Peel off the paper (without splitting the pins) if it does not lie flat. Notches are made along the line of connection with the sole in the toe area, the pattern lines are adjusted. The resulting pattern can be divided into several parts, depending on the model you have developed (Fig. b).

6. What and how to make homemade boots

The details of the top of home boots made of leather, split leather, felt, thick cloth, leather set (from different pieces of leather) are cut. The details of the top can include pieces of tapestry, velveteen, cloth, fur. Do not forget about 0.5-0.7cm seam allowances.

According to the same patterns, the lining is cut out, using split leather, cloth, baize, woolen knitwear, fur for it.

Stitch the top and lining separately. So that the backs do not crumple, a leather heel is attached to the lining inside the boot. Along the edge of the boots, the lining is connected to the upper part with an inner seam, then turned right side out, and a reinforcing stitch is given.

The edges of the neckline can be processed with a braid or a leather edging strip, a leather braid if the lining is made of split leather, fur or knitted lapels (Fig. D).

They fix the upper part of the boot to the sole in the same way as slippers, fitting the upper part in the toe part and a little in the heel area. The seam is laid from toe to heel in both directions. If you attach in a circle, then due to the fit, the shape of the boot may be deformed, warped in one direction.

If the circumference of the upper part of the boot turned out to be larger than the soles, then the excess is taken into the heel seam.

So that children's home boots do not fall off the child during active movements, sew ties to them or pull them off with a strap pulled through the holes punched in the upper part. If the lining is made of fabric, then put metal blocks in the holes.

7. Ideas for sewing slippers with your own hands

It is not difficult to make such slippers from felt or coarse cloth, suede with your own hands. To do this, you just need to remove the top pattern from any shoe and buy a few meters of colored braid. Holes can be punched with a special flat punch or cut with a narrow and sharp knife blade. Any materials can be used as a material, warming and strengthening them with gaskets, including the fur of a sheepskin coat, and for the protective lining of the bottom of the sole - leather from the tops of women's boots.

It will be a little more difficult to make such warm house boots, but they will not only look original and stylish, but also reliably warm your feet. Sew ordinary slippers first, after you learn the technology and working methods, it will be easy for you to sew other models of slippers with your own hands.

Do-it-yourself tilde doll made of fabric

Your daughter's favorite toy will be the tilde doll, which you will sew with your own hands. How to make a pattern and sew a soft fabric doll

How to sew pillow letters

How to sew pillow letters with your own hands. In this article you will learn how to make a pattern volume letters and the technology of sewing such a decorative pillow.

DIY braided belt

How to make a braided women's belt with your own hands. Such leather belt can be sewn from old leather clothes.

DIY phone case

We offer you several ways how you can quickly and easily make a phone case with your own hands from genuine leather.

DIY leather belt

How to make a belt with your own hands. How to make a hole in a belt, fasten a buckle and what tools are needed to work with leather.

How to sew with rubber thread on a sewing machine

To make an assembly on a dress with a stitch with a rubber thread, the elastic thread must be wound on a bobbin.

How to sew curtains on grommets

The technology for sewing curtains on grommets is almost the same as sewing a regular curtain, which even a novice seamstress can do.

Do-it-yourself office chair repair

This article gives the wizard's advice on how to drag an office or computer chair with your own hands. They will help you save money when repairing your chair.

Do-it-yourself hot potholders

Try to sew a potholder yourself, we will help you make a pattern and show you how to sew a potholder-mitt.

#MANUFACTURE_SHOE. #MANUFACTURING_SHOES_with_your_hands. #DIY_CAM Most #shoes, from the cheapest to the most expensive pairs from boutiques and overseas shopping, are made in factories using machines to speed up the process and increase the number of #shoes produced. I dare to suggest that even the best and most accurate machine cannot replace the hands of a professional master shoemaker. The machine will not notice unevenly applied glue, inaccurate processing of the insole, thickening or defects on the skin, and much more that the master sees and feels when working with a pair of #shoes. At handmade the number of inaccuracies and shortcomings is reduced to a minimum! Since quality control is carried out at each individual #stage_of_production_of_shoes, and not at the very end of finished product when nothing can be fixed. An important component of beautiful and comfortable shoes is #shoe_block! Shop #shoes are pulled onto standard #blocks, the task of which is to cover as much as possible large quantity of people. This naturally affects how the foot feels in such #shoes. No two legs are the same. Even a single person has a difference in the girths and volumes of the right and left legs, laid down by nature. Bulk #blocks do not take into account such features. A simple example: you measure # shoes, and they are good in length, but press on the width, or you have a problem leg and the bone does not give rest, or you have a big instep and at the same time a narrow leg. 0:30 — skin cutting; 0:50 — #tailoring_shoes; 1:35 - sizing # shoes; 3:15 - packing #shoes.

We make shoes with our own hands

CHANNEL FOR CREATIVE "#DIY_CAM": the channel was created for those who love life, who love to create #with their own hands for independent, purposeful and creative people. The content of the channel will consist of videos that will tell you how to do various things with your own hands. Moreover, the videos will relate to completely different areas of activity, the main criterion is "#do it yourself". CHANNEL PLAYLISTS: 1. #CARS AND MOTORCYCLES - #BUILDING AND REPAIRS - #MOBILE_DEVICES_AND_COMPUTERS - #DIY - - - - - - + - - - - - - - - - taken under Creative Commons license - Attribution (re-use allowed) from the channel "Stile Italia Tv "—

7.17. LEATHER PRODUCTS

7.17.1. How to use old skin

In capable hands, old leather will always come in handy. From an old belt, you can make reliable loops for the lid of a box, easel, casket. It is easy to make spines for book bindings from trimming belts. Having mastered the techniques of sewing and decorative leather finishing, you can make a leather watch strap or a hanger for a coat or jacket to your liking.

Leather can both decorate and prolong the life of mittens or gloves if you stick or sew leather circles on the palms or fingertips of gloves - the places that wear out the most.

How to make shoes with your own hands? Step by step master class

Leather patches can reliably mend thick woolen socks. Moreover, if you sew to such socks leather soles, they will replace your house slippers. Scraps from old leather can be used to trim frayed cuffs or elbows of sleeves, pockets of jackets, raincoats, and jackets. And what beautiful buttons they make! All this can be done from old suede. But in addition, it can also be used as an ideal washcloth for washing windows, tiles or as a wipe for glasses. Finally, from leather scraps, you can cook protein fertilizer for growing vegetables. The gray powder obtained after boiling in water contains 9-14% nitrogen and many valuable trace elements. It increases the yield of potatoes by 30%, tomatoes - by 35%.

7.17.2. DIY shoes

Of course, repairing and decorating leather and non-leather products with leather is interesting and useful for home wardrobe. But it is even more exciting to learn how to sew from leather. Where to start here? First of all, with the choice of raw materials. So, home shoes can be made from drape, fur, felt, leather. For the sole parts, it is desirable to select soft leathers; unpainted yuft is suitable for stitches. If the insoles are double, then the lower one is made of dense, durable yuft, and the upper, inner one is made of soft yuft, fur or fabric. For lining, you can use knitwear, wool fabrics, flannel, fur.

You will need to take a few measurements to ensure that the shoes fit exactly on your foot. Take a tape measure and wrap the widest part of the foot at the base of the toes (1); foot in the place of greatest rise (2); measure the oblique instep all around from the instep through the heel (3) and the thinnest point in the tibia (4). For a more accurate cut, measure the length, width of the foot, the distance from the toes to the instep, the protrusion of the heel, the maximum height of the heel (Fig. 121). Home shoes are used for relaxation, so they should be very comfortable. It is better to leave small allowances so that the shoes are spacious enough.

If you have some woodworking skill, it is highly recommended to make a permanent last in the shape of your foot. It's not difficult at all. Cut off the extra sections on the workpiece, taking into account your measurements, and round off the bumps with sandpaper. Cut out a block with the outlines of your foot from the board. It will be very useful for you when finishing the sole.

You can sew amazingly comfortable and easy-to-use "bast shoes" (Fig. 122). This soft, lightweight shoe is made from a single piece of leather in a pleated process. Cut the insole separately. Choose the size according to the picture. Various sock shapes are possible. Approximately open a whole piece of leather or assemble a panel. Put your foot on it and make adjustments after trying it on. If the number of folds is too high, small wedges are needed. The remaining edges can be left free or braided. Small thick folds look better, but they should be located no more than 1-1.5 cm apart. Prepare a strong soft strap no wider than 0.5 cm. Fasten the back with a separate strap, glue the free wedge inside (Fig. 123). Draw a pattern, scour the hem allowance, fold and glue 1 cm (Fig. 124). Attach the insole and make slots for the strap (Fig. 125). Collect "bast shoes" on the strap, pay attention Special attention on a beautiful arrangement of folds in front (Fig. 126). Glue or sew the sole in one of the ways.

|

| Figure 123 |

|

| Figure 124 |

|

| Figure 125 |

| Figure 126 |

|

| Figure 127 |

The following slippers are more traditional. The easiest sewing option is to attach a transverse strip to the sole (Fig. 127). Put your foot on the insole, cover with a strip on top and glue it to the insole, taking into account the rise of the leg. Cut off the excess edges. These operations are done first with paper parts. Carefully separating them, you will get a pattern. Measure the length of the insole along the edge and prepare a braid or leather strip for piping. Sew the ends of the strip at a 45° angle. Treat the insole with a piping or braid. Scrape the ends of the piping along the entire length to thin the leather, after which you can sew the piping to the insole. The braid can be made from a thin lace or dense thick threads (Fig. 128).

Slippers with a closed toe are warm. To make a pattern, you can use some old slippers lying around at home. Spread them at the seams, circle the individual parts on paper and transfer to the skin. It is better to use whole pieces of leather or a discreet symmetrical set.

| Figure 128 |

Slippers with an open back are shown in fig. 129. Prepare the sole, insole, two parts of the sock - the top with decor and the bottom - from the same material as the insole. Glue both parts of the sock together, braid the top edge. These slippers can also be processed with piping. In this case, the upper edge of the sock is processed either with piping or with fur. Insoles can also be cut out of fur. Lay the sole with the insole with foam rubber (or better - with Vatelin) and glue it together. Connect everything together and braid the curved edges. The arrows indicate the sequence of operations.

Slippers with a closed back are cut differently. Sole, insole, two upper symmetrical parts made of leather or the same material as the insole. The upper parts are connected by two seams on the toe and heel. On the toe, first think up and sew on the decor. Lining parts are connected in the same way as leather ones, and glued with rubber glue to the outer ones. Finish the inner edge of the slipper with a piping. Glue the top of the slippers to the insole with rubber glue 0.5 cm from the edge. Treat the slippers with a piping or braid.

|

| Figure 129 |

|

| Figure 130 |

The most suitable leather for home shoes (Fig. 130) is suede or split leather. The boot consists of 5 parts: the front, two symmetrical sidewalls and the tongue (Fig. 130a). Cut out the tongue approximately and adjust to the desired shape last. The inner shoe from a warm lining is cut out in the same way, but the height is 0.5 cm less than the outer one. Connect the sidewalls and the front part with a turn seam (Fig. 130, b). Cut the single top edge to nothing. Tap the seams with a hammer. FROM wrong side glue linen strips of a slightly shorter length to them and unstitch (Fig. 130c). Connect the upper part of the boot with the insole with an inverted seam. Break both parts with the right sides inward and sew (Fig. 130d). It is best to stitch with thick threads by hand, piercing holes with an awl. Moisten the skin with water and tap the edges to the sole (Fig. 130e). Turn the boot right side out and hammer again. Insert lining. Glue the sole firmly to the insole and tap with a heated hammer over the entire surface. The sole can be sewn on as shown in Figure 130e. In the front part, make holes with a 2 mm punch and approximately collect along the leg. Place the tongue on top and fit close to the front of the boot, adding 3 mm to the braid. Reduce the straight edge to nothing, perforate the curved side. Connect the tongue to the boot with a leather cord braid (Fig. 130g). Check that the lining and leather boot match exactly without wrinkling. Adjust the raw upper edge of the boot inward by 1 cm, overlapping the edge of the lining, and sew 0.5 cm along the entire length (Fig. 130h). Glue a warm insole to the inside of the sole. Shoes like this have been worn since antiquity.

Shoes made of genuine leather, by default, are considered the highest quality.

How can you make your own shoes?

For its manufacture, various animals are used - pork, calf, ostrich, deer, etc.

The cost of products differs depending on what types of material the shoes are sewn from. So, for example, various budget products are made from inexpensive pigskin, from crocodile - exclusive, soft and durable calfskin is used to make branded products.

Each of the varieties has its own characteristics and advantages, based on which they choose the material for sewing a particular pair.

Skin types

Pork

The material is not soft, flexible, it is rough and is not used for the manufacture of exquisite model products. At the same time, it is one of the cheapest and fairly durable types, which makes it possible to produce demanded and inexpensive economy class products. Also, the advantages of pigskin include a high rate of water resistance.

Pressed

The material is produced from crushed waste leather shoes. After grinding, the pieces turn into dust, then a special binder is added and pressed into sheets. Shoes made of this material have some properties of genuine leather - they are hygroscopic, allow the feet to breathe, but are inferior in strength to products made from natural materials.

These products are budget products.

cattle

This species includes the skin of a cow, bull and calf. As a rule, a pair of the middle price segment is produced from this material. High-quality and affordable products are made from very durable and reliable cowhide leather. Such shoes are durable and have an optimal ratio of product quality and its cost. The only caveat is that the skin of an adult animal usually has defects from insect bites, so sometimes minor traces of damage can be seen on the product.

The skin of a bull is coarser and inferior in price to a cow. The skin of a young calf is somewhat inferior in strength to adult animals, but in terms of softness and flexibility it gives a significant head start, moreover, it usually does not have such damage. highly elastic soft material lends itself well to all types of processing and can be used for branded models. Often in stores you can see shoes with a recognizable snake or crocodile pattern at an inexpensive cost. In fact, these are calfskin leather shoes, embossed.

Sheep

Optimal for the manufacture of model products. Distinguished by softness and tenderness, it is susceptible to weather conditions, so shoes made from it require careful wearing.

reindeer

Expensive quality products are obtained from deer skin. The material perfectly holds heat, wear-resistant and durable. Such shoes are not only exquisitely beautiful, but also incredibly comfortable - even in dress shoes you will feel like in slippers. Deer suede is especially popular in the manufacture of boots and clothing.

reptile

The characteristic pattern of reptile skin gives products original look. But the value of such shoes is not only in this. The material is very strong, wear-resistant and durable, so shoes made from it can be attributed to the premium class. Particularly prized are alligator products, which can cost several thousand dollars. These products are exclusive.

Premium-class products are sewn from crocodile, and the caiman has the most affordable price. The latter, unlike alligators and crocodiles, is quite tough and inferior to them both in aesthetic terms and in durability and quality. The advantage of caiman shoes is an attractive cost.

Snake skin is slightly inferior in cost to crocodile skin, but it also belongs to the premium class.

ostrich

Products can be called piece, they all belong to luxury models. Soft skin makes it very comfortable to wear.

Types of leather depending on processing technology

Shoe manufacturers produce products from polished, embossed, laminated leather, etc. What types of leather are sewn from depends on the purpose of the product.

Nubuck

Natural nubuck is a polished leather. Thanks to polishing, the surface of the products is velvety, soft. Matte material has the effect of absorbing light and looks expensive and presentable. It is recommended to wear shoes made of natural nubuck in dry weather.

If the nubuck is impregnated special means, such material is called nubuck oil. Products made from it are more unpretentious in wearing and durable.

Suede leather

Produced using fat tanning technology. In the process of processing, a smooth front surface is removed from the skin of animals (mainly young calves, deer). Sometimes suede is processed from the inside (bakhtaryan), sometimes from the front.

The characteristic features of the material are high hygienic properties, increased ductility and softness. in a sock suede shoes comfortable and waterproof.

Velours

A kind of buffed leather. For the production of velor, the skins of goat, chevreta, calf (calf up to 6 months), outgrowth are used. The material is processed from the inside, therefore, as a rule, animal skins with numerous defects on the front side are used.

The hairiness of velor resembles suede, but is inferior to it in properties. Velor footwear is afraid of water and dirt, and its form stability leaves much to be desired.

Lacquer

Produced from chevro, calf, goat. The surface of the skin is coated with varnish or polyurethane resins. This results in a very smooth glossy lacquered surface. Shoes made from it require special care and handling. It is not recommended to wear patent leather shoes or boots with a patent leather top in rainy weather; heat over 25 degrees and sub-zero temperatures are also contraindicated for them.

Genuine leather shoes are a great option for any season. In addition, it is also an environmentally friendly product, since it does not contain chemicals.